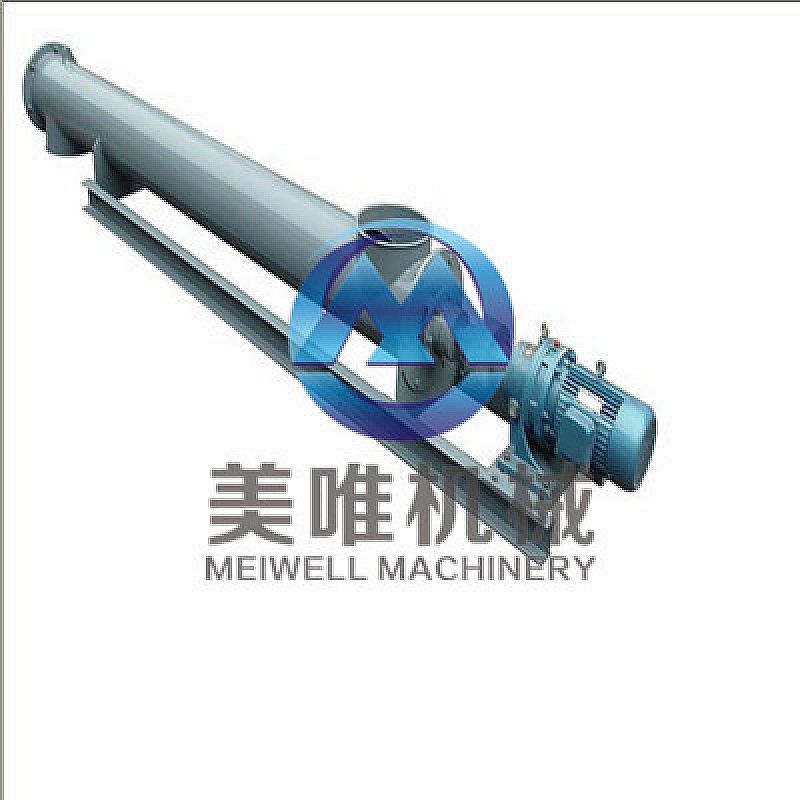

GLS screw conveyor

| Item No.: | IFA-XCW359685 |

Introduction:

GLS tube type screw conveyor is widely used in various industries, such as building materials, electric power, chemical industry, metallurgy, coal, aluminum and magnesium, machinery, light industry, food and food industry; Apply to level or less than 20 ° angle. Screw conveyor is simple in structure, low making cost, sealing strong, discharging and operation convenient advantages. Centre can multi-point feeding, need not mobile device drivers, remove crane bearing, don't remove spiral , can lubricate crane bearing needn’t demolish cover plate. The machine has high reliability, long service life, good adaptability, easy installation and maintenance.

1. Big carrying capacity, safe and reliable.

2. Adaptable, easy installation and maintenance, long service life.

3. The small size, high speed, ensure rapid uniform transmission.

4. The discharge end install cleaning device, the low noise, strong adaptability, in and out of the material mouth position arranged flexibly.

5. Good sealing, the shell is made of seamless steel tube, the end use flange connection as a body, good rigidity.

1. Driving device

2. Head bearings

3. Discharge hole

4. Front part

5. Middle part

6. Tail part

7. Feeder hooper

8. Tail bearings

Technical Parameter:

|

Equipment parameter |

GLS100 |

GLS120 |

GLS140 |

GLS160 |

GLS200 |

GLS250 |

GLS300 |

GLS400 |

GLS500 |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

||

|

Helicoid diameter mm |

88 |

108 |

140 |

163 |

187 |

240 |

290 |

360 |

436 |

|

|

Shell diameter(mm) |

114 |

133 |

168 |

194 |

219 |

273 |

325 |

402 |

480 |

|

|

Allow transmission angle

|

0-60 |

0-60 |

0-60 |

0-60 |

0-60 |

0-60 |

0-60 |

0-60 |

0-60 |

|

|

(α°) |

0-30 |

0-30 |

0-30 |

0-30 |

0-30 |

0-30 |

0-30 |

0-30 |

0-30 |

|

|

|

0-15 |

0-15 |

0-15 |

0-15 |

0-15 |

0-15 |

0-15 |

0-15 |

0-15 |

|

|

(m) Max transport length |

8 |

8 |

10 |

12 |

13 |

14 |

15 |

16 |

16 |

|

|

10 |

10 |

12 |

16 |

17 |

18 |

21 |

22 |

22 |

||

|

12 |

12 |

15 |

20 |

22 |

25 |

27 |

28 |

28 |

||

|

Max transport capacity(t/h) |

6 |

12 |

18 |

30 |

48 |

80 |

110 |

140 |

180 |

|

|

4 |

8 |

13 |

22 |

30 |

50 |

70 |

100 |

130 |

||

|

3 |

6 |

9 |

15 |

20 |

35 |

50 |

60 |

80 |

||

|

Transmission power (KW) |

|

0.75-2.2 |

0.75-4 |

1.1-5.5 |

2.2-7.5 |

3.11 |

4.15 |

5.5-18.5 |

7.5-22 |

11.30 |

|

1.1-3 |

2.2-5.5 |

3-7.5 |

3.11 |

5.5-15 |

7.5-18.5 |

11.22 |

11.30 |

15-37 |

||

|

2.2-4 |

4-7.5 |

4.11 |

5.5-7.5 |

7.5-18.5 |

11.22 |

15-30 |

18.5-37 |

22-45 |

||